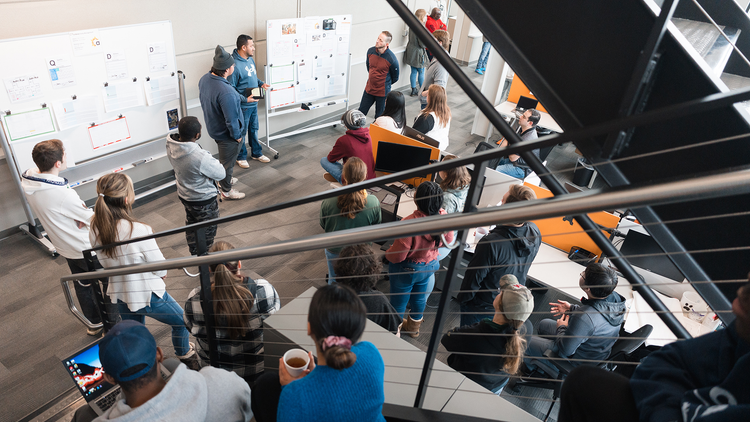

Breakthrough Campus

Breakthrough Campus - Fargo, North Dakota

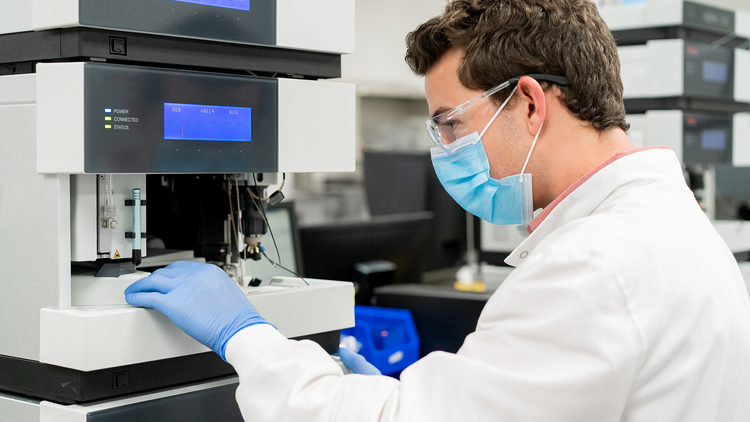

cGMP and GMP-Source® Production of DNA, RNA and Protein

265,000 square feet of new, purpose-built construction

Aldevron’s Breakthrough Campus serves as HQ and as one of the world’s largest cGMP plasmid DNA manufacturing facilities. Breakthrough has been purpose built with the latest innovations and state-of-the-art equipment to produce DNA, mRNA drug substance, mRNA drug product, and protein. We serve thousands of clients, and each project is supported by an expert team delivering unmatched quality of product and experience – all backed by our strategically focused operations pathway ensuring efficiency along with scalability, to deliver the critical raw materials you need to accelerate your path to the clinic.

Certifications & Inspections

In November 2024 we completed our third successful regulatory inspection since 2021. The FDA conducted an unannounced Level 1 surveillance inspection resulting in No Actions Indicated (NAI).

In June 2024, Aldevron received a Certificate of GMP Compliance of a Manufacturer from the competent authority of Germany for an inspection. The scope of the certificate is for mRNA as an active ingredient in the production of vaccines for clinical trials – Not Sterile.

This manufacturing facility was visited by the Center for Biologics Evaluation & Research (CBER) in November 2021. CBER conducted a Pre-License Inspection (PLI) and a general GMP audit of Aldevron, LLC. No Form FDA 483 was issued, and the inspection was classified as no action indicated (NAI)

Purpose

- Aldevron headquarters

- Manufacturing

- Quality and regulatory

- Ultra-low temperature freezer storage and distribution

- Administration

Capabilities

- cGMP and GMP-Source™ manufacturing of plasmid and Nanoplasmid DNA

(supercoiled and linear) - cGMP manufacturing of mRNA drug substance and drug product with LNP encapsulation through sterile Fill & Finish

- cGMP manufacturing of protein

Fast Facts (as of the end of 2022)

- More than 5,000 lots of GMP-Source® & cGMP DNA produced

- Supporting more than 1,000 advanced therapeutic companies worldwide

- Part of nearly 1,100 global clinical trials

- More than 100 mRNA drug substance batches in cGMP programs

Key Facts

- FDA Establishment Identifier 3015047170

cGMP Manufacturing

- 32 production suites that are state-of-the-art modular cleanrooms

- Advanced independent air handling systems for cell banking, inoculation, and fill/finish

- Designated client-specific and newly established mRNA production and fill/finish suites with capabilities to handle flammable liquids and BSL-2 classification

- Multiple 30L and 300L single use microbial fermenters

- 100% single-use consumables utilized for maximum efficiency

- Multi-product capability

GMP-Source® Manufacturing

- 13 production suites

- ISO7 classified dispensing suite

- pDNA focused – supercoiled and linear

- Batch and Fed-batch fermentation at 30L and 300L scale

- Stand-alone cell bank qualification/yield test lab