Aldevron Breakthrough Blog

How Did My Project Get So Expensive?

July 13, 2022 / by Larry Lockwood, Ph.D.

The Hidden Costs of Multiple Tech Transfers

Move fast. Limited funds. Novel ideas. These are consistent themes I’ve noticed in conversations with hundreds of biotechs over the last 20 years, and rightly so. However, these elements sometimes overshadow the need to evaluate the complexities and costs associated with GMP manufacturing in support of a clinical trial, along with what’s needed for manufacturing at phase III and beyond.

Going beneath the surface

For many innovator companies, the default pathway to GMP is to find a CMO with a timeline and capacity in line with their clinical milestones, letting them meet obligations to venture capital investors.

While this process seems straightforward, some key pieces of the decision tree are often missed, such as the ability of the chosen partner to scale-up, provide phase-appropriate services and provide regulatory insights on the journey into later stage clinical trials.

Unfortunately, these shortfalls are not apparent until the transition to phase II or phase III, when the realization sets in that a new manufacturing partner is required to meet regulatory scrutiny.

Added delays and costs

Conducting a second tech transfer from the original GMP partner to a new vendor at a new facility with new personnel immediately presents a hurdle to therapeutic development in terms of time, money and risk.

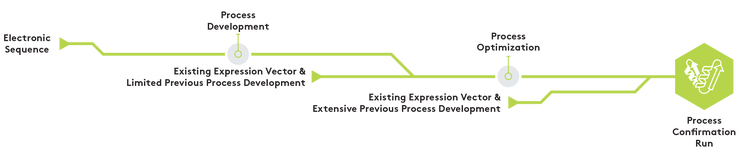

Initial tech transfer to a new CMO usually entails process development to improve yields and consistency, as well as adjusting unit operations to be in line with equipment available at the new facility (i.e. automated chromatography versus manual chromatography). This stage culminates in a feasibility run (best if performed at intended GMP scale and no less than 1/10th GMP scale) to demonstrate the process from start to finish in a non-GMP environment. This establishes the new CMO’s ability to produce material of suitable quality. A risk to note here is that more than one feasibility run may be needed, adding to delays and expenses.

Once a successful feasibility run closes tech transfer, the program is primed for engineering batches to lay the foundation for GMP manufacturing. Depending on the complexity of the process, the time frame for a single tech

transfer consisting of the steps outlined above can be from 3-18 months, with attendant costs ranging from a few hundred thousand to several million dollars.

More steps, more risk

Beyond adding time and cost, when a manufacturing process is transferred to another CMO more suited for phase II through commercialization, the sponsor reintroduces manufacturing risk to their program. Any facility or significant process change after the initial clinical material was made requires a bridging study to demonstrate comparability to the original process approved in the IND filing.

CMO changes may entail unit operation changes which can impact the performance of the drug substance in terms of potency, yield, impurity profile, or ability to formulate into a finished drug product. The additional manufacturing risk introduced at this stage can be avoided by selection of a competent CMO that can accommodate innovator needs throughout the life cycle of the program.

Begin with the end in mind

Leadership teams at innovator companies should consider the value added to their therapeutic program by working with a CMO partner that can deliver phase-appropriate services from pre-IND through commercial GMP production. The benefits of that choice are the avoidance of hidden costs and additional risk inherent in a program that engages two tech transfers on the path to a BLA.

- Want to learn more? Contact Larry Lockwood with your questions

- Have an idea for a topic? Let us know!